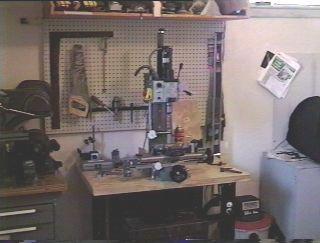

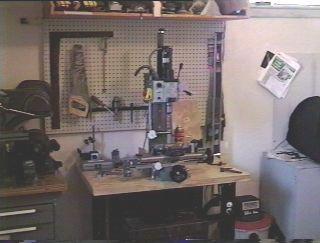

Workbench with

vertical mini-mill to the left and 8 inch lathe to the right. The workbench in the foreground has

a robot under construction. We closed in our two-car garage in the mid-1990s and

my wife and I spend most of our time out here. Her workbench is just out of this photograph to

the right, and we share the center bench for large projects. My son Stephen and I rebuilt a vintage

Honda Mini-Trail here from a pile of parts we rescued from an old barn. He and his brother Jonathan

built their R/C airplanes on this bench when they were able to shoo their parents away. Mostly these

days it is covered with robot bits and pieces and my wife's costume jewelry debris.

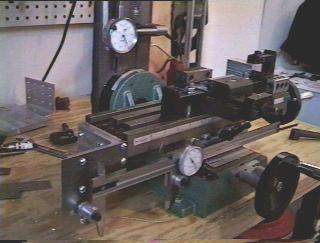

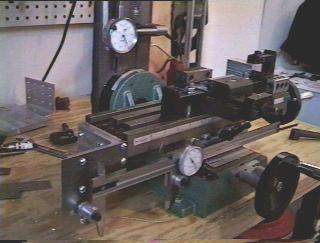

Emco-Maier Compact 8 Lathe sold by Sears in the before-time under the

Craftsman label.

I've added three and four-jaw universal and independent chucks, a 7 inch faceplate, a milling

attachment, and a couple of different tail stock chucks. The cabinet underneath contains

these and other miscellaneous tooling. This was my first real machine tool, and for a while

I fabricated all the robot parts for SR04 and previous versions with the lathe and lathe-plus-

milling attachments. It weighs about 150 pounds and seems to me exactly the right size, midway

between the model-makers lathes like Sherline and Taag and the "real" lathes like the 9" Southbend

that most of my machinist friends' seem to admire. I believe I am the 5th owner of this lathe;

all the previous owners were professional machinists and took excellent care and maintenance.

Atlas AH10 Vertical Mini-Mill sold by Grizzly as the G8689

After a few years of milling with my lathe I decided I needed a separate milling machine, so that I could

leave the lathe configured as a lathe and the mill configured as a mill. While the lathe did excellent

service as a horizontal mill, the extra time needed to reset and indicate in the two different setups

really added up on a large project. I looked at various desk top mills, mill drills, full size industrial

milling machines, and finally settled on this Atlas mini-mill. After making several modification I have

been quite pleased with this inexpensive little machine. The only complaints I have were that I had to

replace the plastic gears in the gear-head with metal gears, which fatigued after only a few months of

nominal wear, and I had to have the table ground flat. As received it was off from one end to the other

by about .008 inch. A local machine shop ground it flat to .001 inch for $50, money well spent.

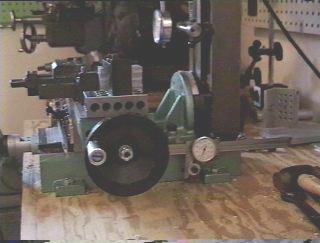

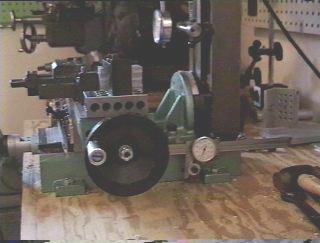

Closeups showing dial-calipers used as "poor mans DRO"

The axis on the mill uses 16-turns-per-inch threads rather than the more common 10, and this makes

for somewhat clumsy conversions to thousands, i.e., 62.5 thousands per revolution of the hand wheel.

After a year of

doing modulo 62.5 math I bought a couple of dial-calipers and built mounts for the X and Y axis of

the mill to provide more convenient metrics for layout and machining. These photos are closups

of the mini mill show dial-calipers attached to the X and Y axis as a "poor mans" DRO (digital readout).

Note also the dial indicator mounted on the vertical axis for depth metric. These give the

mill table a repeatable positioning accuracy as measured with a separate indicator of .0005 inch. The

quill travel is about 9 inches and so this little machine serves as a drill press as well. I

do most of my layout work using this table and edge and center finders.

Electronics workbench and Bun's jewelry corner.

The electronics workbench is where I build and test the robot brains and sensors. The

SR04 robot

is in the center of the bench in this picture, with a

Tektronics 475 dual trace 'scope and a

digital multimeter on the right. A bench power supply and signal generator sit on the shelf

above the robot, and a Weller soldering station on the bench next to the 'bot.

At the opposite end of the shop is Bun's workbench where she creates her jewelry. She sells it

mostly backstage at the opera to visiting singers, so her creations are worn in opera houses

all over the world. She also appears to have a significant investment in plastic storage

containers. :) You can see some of her

angel pins and broaches here

Atlas Horizontal Mill circa 1950. This is a restoration work in progress by Duane Gustavus.

These are the little milling machines that Rosie-the-Riveter used to build tanks

and munitions

while her man was away fighting WWII. It is in excellent shape, and is roughly the same

vintage as me!

Nbot robot platform exploded views

Click on the above image to see some robot parts manufactured in my home machine shop.

to my geo department homepage

to my personal stuff homepage

to my robots homepage